By Products

Welding Machine

By Application

Automation Production Line

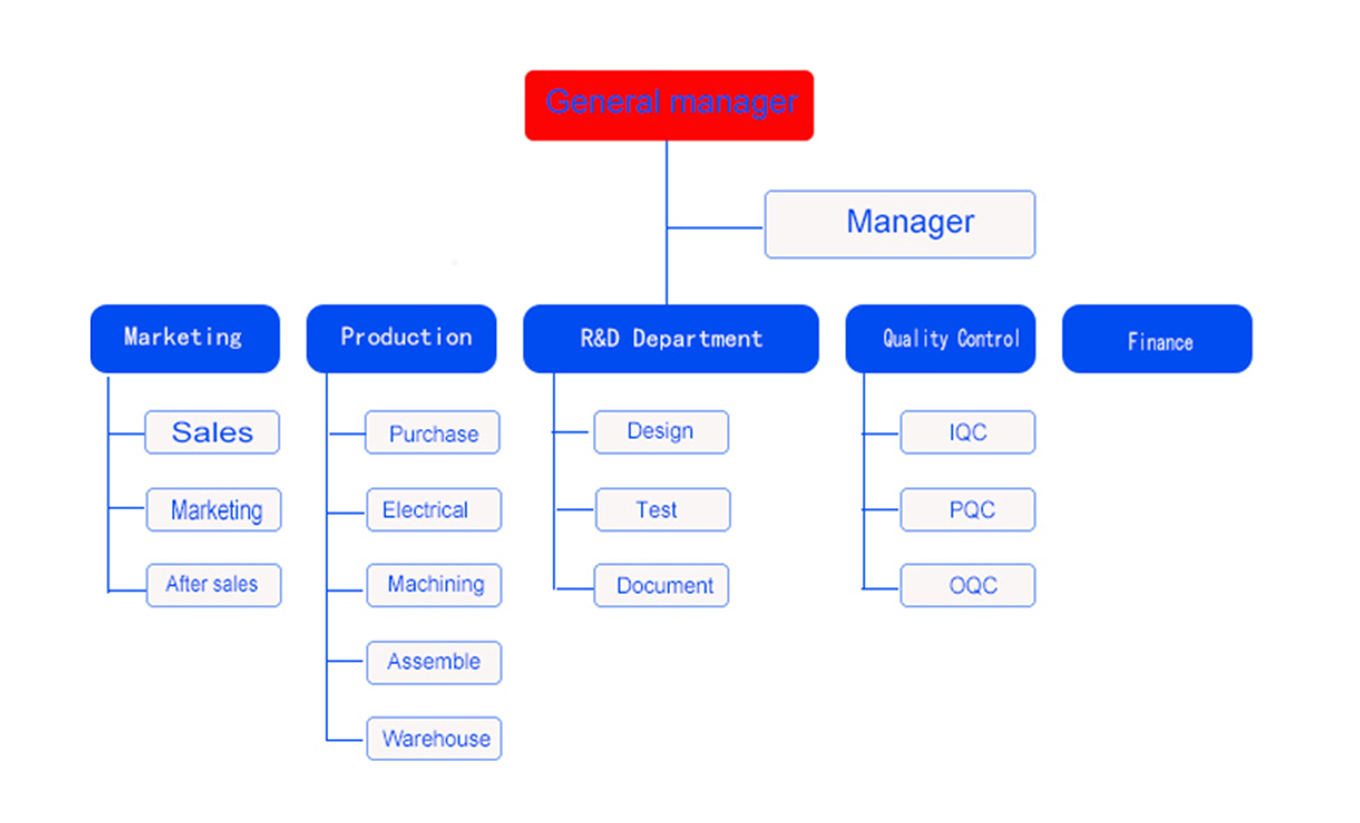

Ningbo Xihe Automation Equipment Co., Ltd. is located in Yinzhou District, Ningbo, China, an important port city on the southeast coast of China and the economic center of the south wing of the Yangtze River Delta. The company is 20 km away from Ningbo Airport, 15 km away from Ningbo Port and 2 km away from the highway entrance. The transportation is very convenient, which facilitates the shipment of goods, and also provides convenience for welcoming you to visit the company.

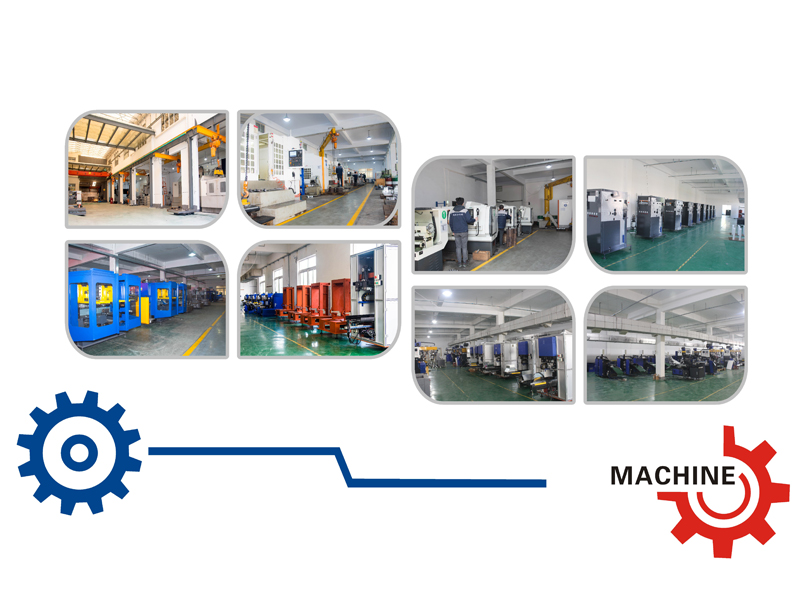

Ningbo Xihe Automation Co., Ltd. can customize the production of various non-standard automatic welding equipment according to the different needs of different customers. The company has a professional R&D and production team, with high-precision CNC machining machines, grinding machines, milling machines, and machining centers. The company can design and produce automation equipment according to the customer's specific product size, thickness and quality requirements, and solve the problems of difficult welding, labor recruitment, material saving, and free hands for customers.

Ningbo Xihe Automation Equipment Co., Ltd. is positioned in the research and development and sales of automatic welding equipment. The equipment sold includes paper drums, mesh baskets, sample sieves, glass covers, brake shoes and other industries. Based on integrity and pioneering spirit, we will promote the "five-in-one" business model of scientific research, production, brand, market and after-sales, and sincerely cooperate with new and old customers for common development.

All fasteners use national standard 12.9 grade

The frame is processed and welded with high-strength steel plates, and the shell is assembled and wrapped with thickened aluminum profiles.

The accessories are processed by the gantry machining center and the slow-moving wire

The surfaces of all accessories have been treated with blackening, electroplating, oxidation, painting and plastic spraying.