By Products

Welding Machine

By Application

Automation Production Line

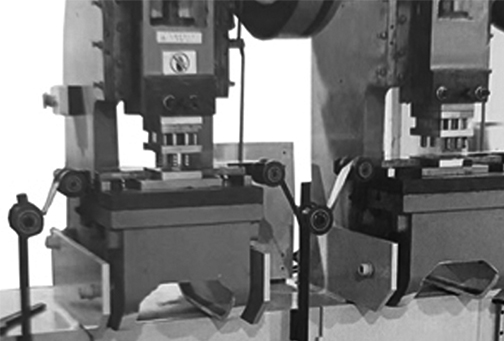

The equipment clamps the steel back of the brake pad through the fixture, and uses the medium frequency welder to conduct single or continuous spot welding on the product.】

Hot Recommended Brake Pad Spot Welder: light weld 1500 laser welder.

Adopt intermediate frequency controller, high welding control precision.The output current is stable, achieving the effect of energy saving.

The equipment has the function of single and continuous spot welding, eliminating the need for manual switching of welding work. High-flexibility multi-layer copper tape is used for electrical conduction, with high electrical conductivity.

The scrap rate is low. When the current is abnormal, the equipment will automatically alarm and stop. The hydraulic angle cylinder is adopted, which improves the clamping force and the welding quality and appearance of the product.

The equipment has the counting function to count the welding times, which is convenient to understand the production on duty, greatly improving the work efficiency.Three phase power input, small transformer loss, and significant energy-saving effect.

The three discharge pulses can be set separately and used separately or in any combination. High flexible multi-layer copper tape is used for conduction, which has the advantages of high conductivity, good heat dissipation conditions, convenient maintenance, etc.

News

News

News