By Products

Welding Machine

By Application

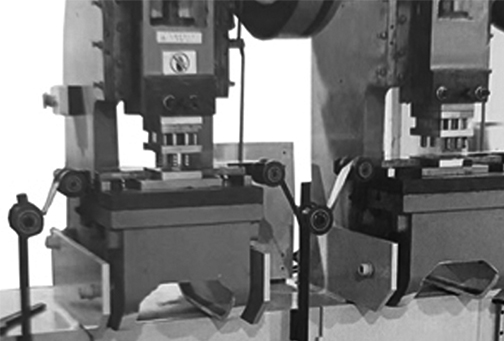

Automation Production Line

The equipment completes a series of automated processes through driving wheels to transfer materials, rounding after clamping by clamps, laser continuous welding, conveyor belt transmission, and crimping.

This equipment is mainly used for the production of stainless steel welding and forming of trash cans for hotel supplies. It is a special equipment for high-end trash can manufacturing. The device is easy to operate and adopts a touch screen to control the setting of operating parameters.

The width of the steel strip can be adjusted freely without changing the mold. The equipment should be controlled through the exchange of information and the next process can be added at any time. The mechanical action adopts servo digital control to reduce product replacement time.

The equipment is divided into two parts: welding and crimping, which are connected by a feeder to complete fully automatic production. Welding adopts laser continuous welding technology. The crimping method is reversed without adding any lubricant. This is ideal for high-end trash can manufacturers.

The equipment adopts continuous laser welding technology. The welding speed of the equipment can reach 10-15 pieces/1 minute, and the welding width can reach 50-160mm.

The thickness of stainless steel is 0.2-0.8mm (when the thickness of the steel strip is greater than 0.5, the width of the steel strip is not greater than 80), and the welding diameter of the steel ring can reach φ200-650mm, which is an ideal production equipment for hotel supplies suppliers.

News

News

News