By Products

Welding Machine

By Application

Automation Production Line

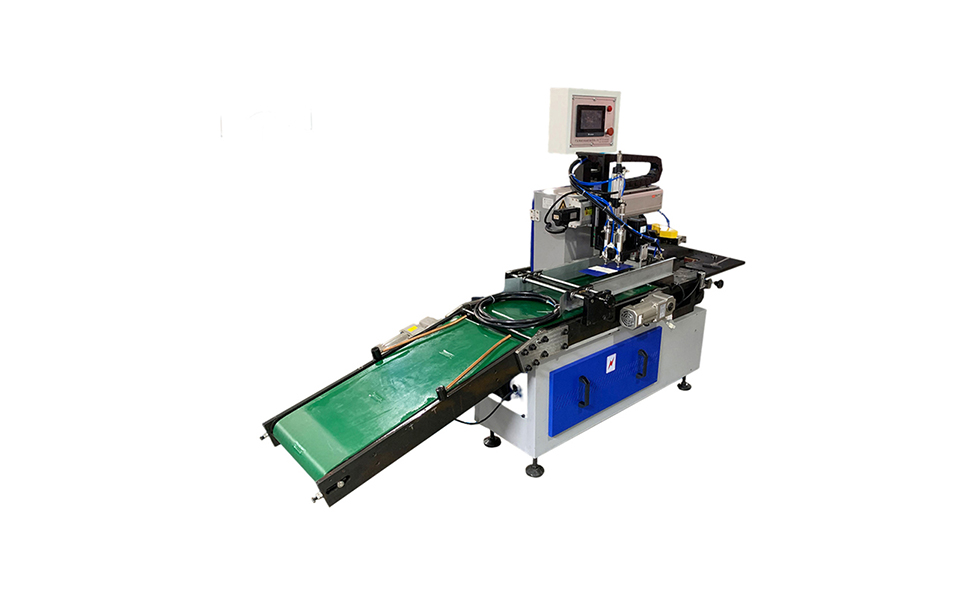

After the stainless steel band of the glass pot lid is crimped and stretched, the angle pressing process is an indispensable process in the automatic line industry of the kitchenware industry. At present, the equipment is widely used in the processing and production of the glass pot lid G-ring and T-ring. The equipment adopts touch screen digital input to control the operation settings, which is simple and convenient to operate, and it is easy to replace the product.

Fully automatic angle press is an ideal special equipment specially designed and manufactured. The device has a wide range of applications and adopts touch screen digital input to control the operation settings, which is simple and convenient to operate and easy to replace.

Equipment accessories (panel rack, control system, drive motor, pneumatic components) are world-renowned brand products. The equipment adopts a programmable controller as the main control unit, with simple circuit, high integration and intelligence, which reduces the failure rate and facilitates maintenance and maintenance.

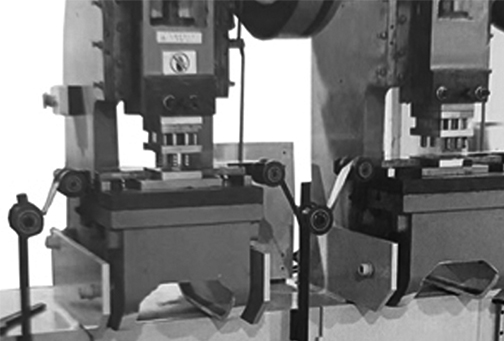

The steel ring that has passed through the edges is squeezed by the corner pinch rollers to achieve the effect of squeezing the edges together and pressing the corners against the upper surface. In addition, it is equipped with a high-precision planetary reduction device, which can improve the positioning accuracy of the product.

The angle press is a process after the steel ring is crimped and stretched, and it is an indispensable process in the automatic production line industry of the glass fiber industry. Fore and aft movement, crimp wheel and robot movement are all controlled by Inovance servo motors.

Product recovery position, robot recovery position, robot discharge position and edge extrusion depth are all controlled by parameters. High control precision, low failure rate and simple operation. The device uses two angular pinch wheels to achieve the effect of edge squeezing.

News

News

News