By Products

Welding Machine

By Application

Automation Production Line

Electric resistance seam welding is a process that uses a resistance seam welder to join two or more metal sheets by creating a continuous weld along the seam. The process begins by clamping the sheets together between two electrodes, which are attached to the resistance seam welder. An electric current is then passed through the electrodes, which generates heat and melts the overlapping metal at the seam. As the metal cools and solidifies, it forms a continuous weld between the sheets.

The key to successful resistance seam welding is the precise control of several important variables, including the welding current, the electrode pressure, and the welding time. These variables are adjusted based on the thickness and type of metal being welded, as well as the desired strength and quality of the finished weld.

The heat source is usually electrical which may be supplied by an arc generator, spot welding machine, or resistance seam welding machine.

High-speed welding of coated steels is of particular importance in the manufacture of tin cans. Specialist consumable wire resistance seam welding machines are used. Quality monitors have been developed for these applications and welding speeds up to about 100m/min are possible.

Any material that melts at approximately the same temperature as that used for electric resistance seam welding will work well as a filler material.

Resistance seam welding is a well-established welding method that has been used in industries such as automotive, aerospace, and electronics. In recent years, research and development efforts have led to several advancements in resistance seam welding technology, which have improved its performance and efficiency in various applications.

One major advancement in resistance seam welding technology is the use of advanced materials for electrodes. These materials have a longer service life, are more durable, and can withstand high temperatures and pressures during welding. This has resulted in increased productivity and reduced maintenance costs.

Another advancement is the integration of automation in the welding process. Automated resistance seam welding systems can monitor and adjust welding parameters in real time, resulting in consistent and repeatable welds. This has reduced the need for human intervention during the welding process, improving efficiency and reducing the occurrence of errors.

Advancements in control systems have also improved resistance seam welding technology. Modern control systems allow for precise control of welding parameters, such as the welding current, voltage, and force, resulting in improved welding quality and reduced welding defects.

Overall, advancements in electric resistance seam welding have increased its usefulness and efficiency, making it an even more valuable welding method for various industries.

Weld joint design plays a critical role in determining the quality and integrity of electric resistance seam welding. In order to achieve a strong and reliable weld joint, there are several key considerations to keep in mind when designing the joint.

The first consideration is the joint type, which can be a lap joint, a butt joint, or a T-joint, among others. The joint type will determine the welding schedule, as well as the electrode design and spacing.

Another critical factor is the thickness of the materials being joined. The thickness of the materials will determine the welding current and electrode force required to achieve a quality weld.

The material being welded also plays a key role in joint design considerations. The electrical conductivity and thermal conductivity of the materials will affect the welding schedule, as well as the electrode design and spacing.

The welding schedule and electrode design are also important considerations for achieving a quality weld joint. The welding schedule should be optimized to minimize heat input and reduce distortion, while the electrode design should be optimized for the particular joint type and material being welded.

Overall, careful consideration of weld joint design factors is essential for achieving a quality resistance seam weld that meets the desired specifications and requirements.

Spot welding and seam welding are two commonly used methods in the welding industry, each with its applications and techniques.

Spot welding involves joining metal sheets by applying heat and pressure to localized spots, while seam welding creates a continuous weld along the length of a joint. Spot welding is ideal for thin sheets and is commonly used in automotive and electronics manufacturing.

Seam welding, on the other hand, is used for creating leak-tight and structurally strong welds in applications like pipe production. Spot welding is automated and quick, while seam welding can be automated or manual.

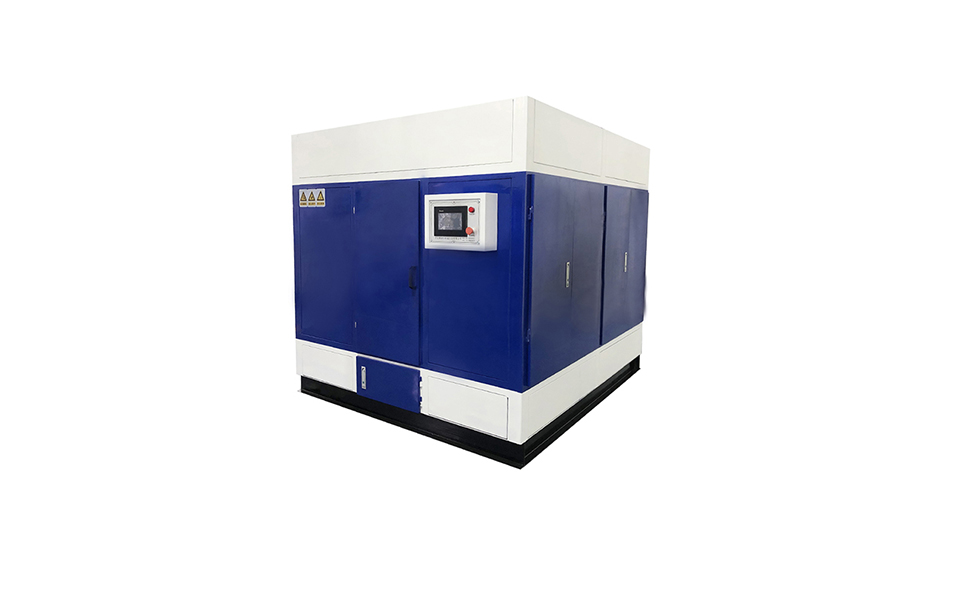

Xihe specializes in manufacturing high-quality spot welding and electric resistance seam welding machines to meet diverse welding needs.

Strong and Durable Welds: One of the biggest advantages of resistance seam welding is that it produces strong and durable welds. The welded joint is strong enough to handle a high load capacity, making it ideal for heavy-duty applications.

High Productivity: Resistance seam welding is a highly productive process that can be used to weld many components at a faster rate than other welding methods. This makes it ideal for mass production applications.

Consistency: In resistance seam welding, the welding current, pressure, and time are all precisely controlled, which ensures that the welded joint is consistent and repeatable. This improves the quality of the welded joint and reduces the likelihood of defects.

No Filler Material: Resistance seam welding does not require any filler material, which makes it a cost-effective welding process. This also reduces the risk of contamination and ensures a cleaner weld.

Automation: Resistance seam welding can be easily automated, which makes it ideal for use in manufacturing processes. An automated welding process ensures that the welding is consistent, reducing the likelihood of human error.

Environmentally Friendly: Resistance seam welding does not produce any fumes or hazardous material, making it an environmentally friendly process. This makes it ideal for use in applications where environmental considerations are a concern.

Limited Material Compatibility: Resistance seam welding is only suitable for certain materials, mainly metals with high electrical conductivity such as steel and copper. Materials with low electrical conductivity, like aluminum and titanium, cannot be welded using this method.

Limitations in Weld Joint Geometry: Resistance seam welding is well suited for straight line welds of constant cross-section. Welds with complex geometries or those having variations in cross-section may not be suitable for this method.

Limited Weld Depth: The maximum weld depth that can be achieved in resistance seam welding is limited. This is because the welding current is supplied to the joint through two circular electrodes, which can only penetrate to a certain depth.

Welding Defects: Resistance seam welding can be susceptible to certain defects such as burn-through, incomplete penetration, and porosity. The occurrence of these defects can be reduced by optimizing the welding parameters and appropriately maintaining the equipment.

News

News

News