By Products

Welding Machine

By Application

Automation Production Line

Designed with excellent performance and high precision, Pot Cover Stainless Steel Belt Laser Welder is widely used in the manufacture of various kinds of high-end and precious products.

Rated total power | Input voltage | Enter the frequency | Product diameter | Product thickness | Product width | Dimensions |

25KW | 3*380V | 50HZ | 63~600mm | <0.7mm | 12~58mm | 2000*1800*1950mm |

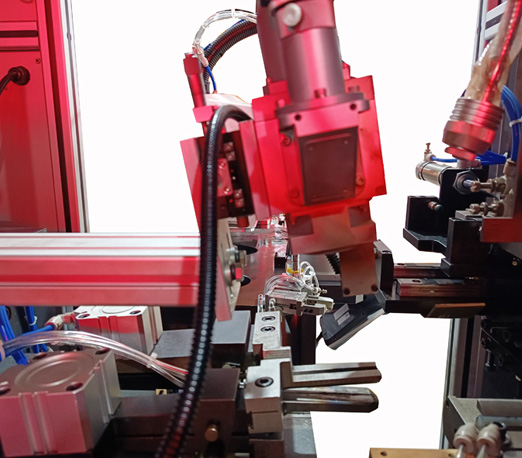

The equipment is suitable for laser welding of stainless steel strips in various industries such as glass pot lids, enamel pots, trash cans, paper buckets, mesh baskets, and sieves. It is suitable for the production of stainless steel rings of various widths, thicknesses and diameters. For laser seamless welding, it solves various production problems such as weak welds, uneven welds, unsightly welds, and waste of materials.

The equipment has high efficiency. It adopts high-precision servo motor feeding and high-speed starting clamping and pushing devices, which can realize accurate cutting and welding of steel strip. The quality is high. The surface of the welded product is smooth and beautiful without burr, and the desoldering rate is less than 0.1%.

Pot cover stainless steel belt laser welder Main Characteristics

The operation is simple and fully numerically controlled, and every worker can operate the equipment after learning.

Arbitrary adjustment, the equipment is controlled by the program, and the welding size can be adjusted arbitrarily.

High efficiency, high-precision servo system is used to start various processing steps at high speed.

High-quality, laser continuous welding makes the welds meet the highest requirements.

High energy saving, the equipment has the alarm system of no material and material jam, and the function of automatic shutdown.

Low cost, the equipment combines multiple processes to complete, which completely solves the labor problem.