By Products

Welding Machine

By Application

Automation Production Line

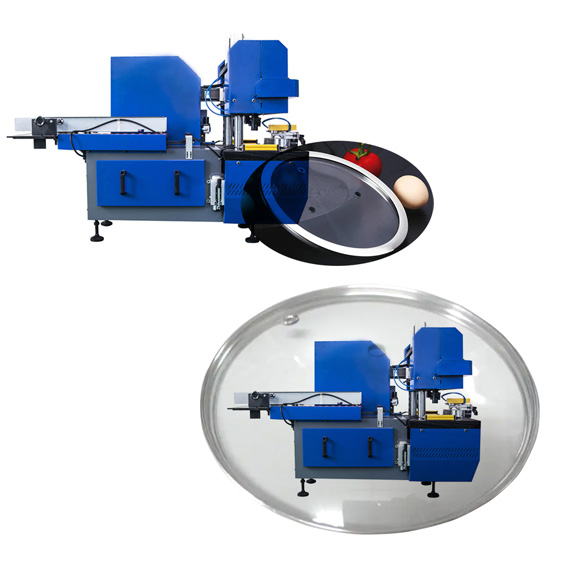

The equipment is used to stretch the workpiece after the welding and crimping process. After the completion of our welding and crimping process, the product will be sent to the stretching machine through the conveyor wheel. The stretching equipment will stretch the workpiece through the high-speed rotation of the stretching die. After the stretching is completed, it will be sent to the next process through the conveyor belt, so as to realize automatic flow production.

Input voltage | Enter the frequency | Product diameter | Product width | Dimensions |

3*380V | 50HZ | 290~400mm | 18~58mm | 1800*1100*1200mm |

The equipment is mainly used in the stretching process of stainless steel strips of glass pot lids in the kitchenware industry, especially the two products of G-ring and T-ring that require a stretching process. Equipment is an indispensable and important part of the automatic production line of stainless steel strip for glass pot lids, and it is an important process of stretching after crimping.

The equipment repeatedly considers the drawing problems encountered in the production of glass pot cover, and solves the problem of slow manual drawing and poor quality by using high-speed rotating drawing die and rolling conveyor wheel. Combined with the rationality of the production efficiency of the whole production line, the maximum utilization rate of the equipment is achieved.

Pot cover stainless steel belt stretching machine Main Characteristics

The steel ring feeding roller is the transmission mechanism from the crimping machine to the edge drawing machine. The speed of the feeding roller is controllable, and the speed of the roller is adjusted according to the size of the product.

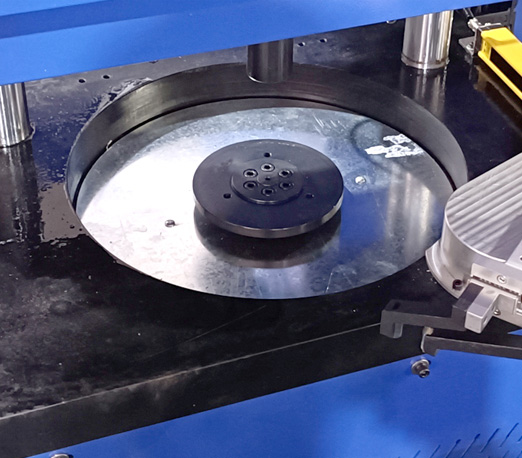

The pallet uses the designated pallet according to the product model and size. To remove the pallet, it can be easily removed as long as the pallet is rotated counterclockwise by hand.

The stretching die is a special stretching die according to the size and model of the product. The stretching die is used together with the upper die.

The upper and lower stretching die is positioned up and down through the lifting and lowering servo. Stretch upper die reclaimer is moved to the tray by the lift servo to reclaim the material.

The manipulator takes out the product from the edge-drawing lower mold and moves to the next process through the positioning of the upper and lower servo of the reclaiming material, the servo of the deflection of the material of the reclaiming, and the servo of the telescopic servo of the reclaiming material.

The adjustment wheel is to adjust the sheet metal parts on the transmission wheel according to the size of the steel ring, shrinking inwards and outwards.