By Products

Welding Machine

By Application

Automation Production Line

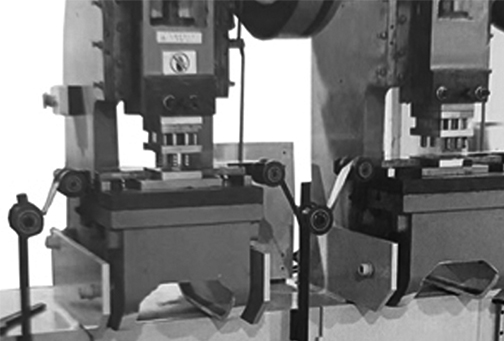

The equipment is fed through the driving wheel, clamped by the clamp and then rounded, welded by continuous laser welding, grasped by the mechanical arm and transferred to the next process, and then unloaded after being formed by four stations.

The equipment is mainly used for the welding and forming production of stainless steel rings for mesh baskets, and is also suitable for welding and forming of stainless steel rings for oil grid products. The hydraulic oil of the equipment is cooled by compressed refrigerant. The equipment consists of four-station molding equipment, with high quality products and less labor.

The equipment adopts continuous laser welding technology and four-station forming equipment to weld and form baskets or grids of different shapes. The surfaces of all accessories have been blackened, electroplated, oxidized, painted and plasticized to ensure the equipment operates properly in relatively harsh environments.

The molds are custom-made and perfectly suited for the processing of the factory's own products. The device is easy to operate and parameters can be adjusted via the touch screen. High production precision, accurate positioning and feeding. Fully automatic production to realize the integration of welding and forming.

The equipment is easy to operate, and adopts the touch screen to control the operation parameter setting, which can automatically complete the process of feeding cutting, welding, crimping, forming and unloading, which greatly saves labor costs.

The post-welding equipment consists of four-station forming equipment with superior production capacity. The hydraulic oil of the equipment is cooled by compressed refrigerant. Equipment is the best choice for mesh basket manufacturers.

News

News

News