By Products

Welding Machine

By Application

Automation Production Line

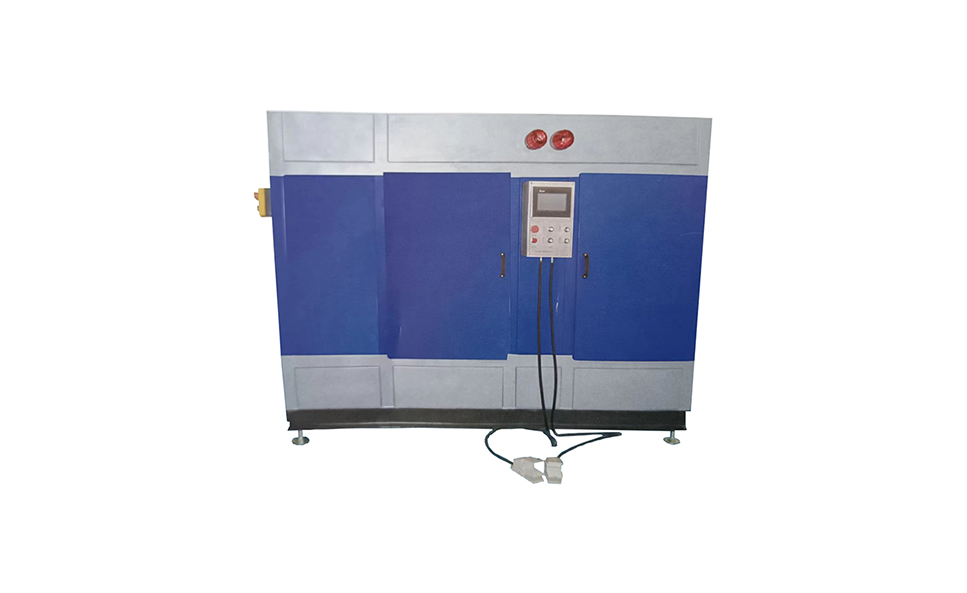

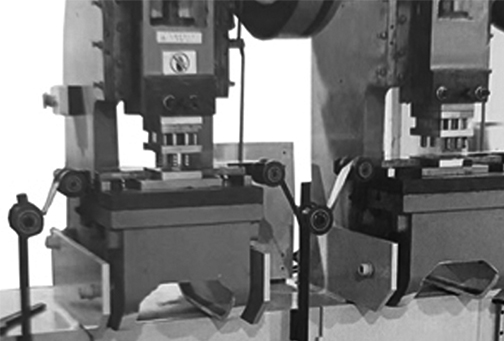

The Dust Cover Welding Machine is a fully automated system that can attach covers to welding machines accurately and efficiently. It employs advanced technology to unload the material automatically onto the waiting tray. The material then enters the hydraulic cutting device, which is operated by a servo drive and falls automatically into the storage table. Afterward, the tool clamps the material, and the gas-shielded welding machine spot welds the product. The automated process ensures a consistent and precise welding quality while significantly increasing the production output. Thus, the Dust Cover Welding Machine is a highly effective tool for manufacturers of welding machine covers.

This particular equipment is primarily utilized in welder dust covers. The equipment comprises two stations, enabling the simultaneous welding of the same type of products or two different types of products. This unique design provides versatility when it comes to welding operations and allows manufacturers to increase production efficiency. Therefore, the equipment is an essential tool for those looking for a reliable, versatile, and efficient solution for welding brake dust covers.

To ensure precise welding and minimal welding spatter, the brake dust cover is continuously spot welded using a gas shielded welding machine. The equipment is designed to maintain uniform welding point size, enhancing product quality. Moreover, the equipment boasts a fully sealed structure that reduces the chances of welding spatters damaging the human body. Ultimately, this feature ensures the operator's safety while delivering high-quality welding results, making the equipment an indispensable tool for those in the brake dust cover manufacturing industry.

The equipment is equipped with a quantitative production function, which minimizes unnecessary waste during production. The device offers adjustable parameters that can be fine-tuned with the touch screen interface. It can simultaneously process two different types of products, enhancing efficiency, and reducing production time. Moreover, the equipment utilizes a servo motor operation, providing users with the flexibility to set the number and position of the solder joints as necessary. Overall, the equipment offers user convenience and excellent production output, making it an essential tool for manufacturers looking for optimal efficiency and quality in their production process.

Dust Cover Welding Machines are increasingly popular in the manufacturing industry and offer several advantages over traditional welding equipment. Here are some of the advantages of dust cover welding machines:

Precision Welding: Dust cover welding machines use advanced welding techniques and settings that provide accurate, consistent welding of covers to welding machines. Traditional welding equipment may be prone to inconsistencies and imperfections.

Efficient Production Process: Dust cover welding machines function as an automated process, capable of producing covers for multiple welding machines in a short period. This ensures efficient and cost-effective manufacturing operations with minimal waste or reworking.

Reduced Dependence on Manual Labor: Dust cover welding machines provide automation to the production process, reducing the dependence on manual labor, leading to increased efficiency and cost savings on the production line.

Versatility: Dust cover welding machines can accommodate covers made of different materials and thickness levels, providing versatility to the manufacturing process.

Increased Safety Features: Dust cover welding machines employ modern safety features such as fully enclosed structures to protect against splashes and burns, and customizable settings to adapt to different welding requirements.

Overall, dust cover welding machines are a versatile, precision tool that provides efficiency, safety, and cost benefits over traditional welding equipment, making it essential equipment in the manufacturing industry.

Although Dust Cover Welding Machines have improved the manufacturing process for welding covers, it is essential to recognize and adhere to strict safety protocols during their use. Here are some safety precautions for dust cover welding machines:

Personnel Safety: The person handling the machine must adhere to appropriate safety policies such as wearing protective clothing, gloves, and footwear to prevent electric shock, sparks, and burns. Operators should also stand clear from the welding area, particularly during the welding process.

Machine Safety: The machine's structure should be fully enclosed to prevent injury due to explosive airborne material and welding spatter. The machine should also be correctly earthed to prevent electrical shock and damage to the electronics.

Proper Ventilation: Smoke and fumes are common byproducts of the welding process. Adequate ventilation is necessary to ensure that these gases do not accumulate in the workspace, leading to respiratory illnesses and other hazards.

Regular Maintenance: The machine should undergo periodic maintenance checks by a qualified technician to ensure that the machine's operating system is working correctly. Any burnt or worn-out components such as wires and electrodes should be replaced immediately to prevent accidents.

Operator Training: All operators and supervisors who handle the machine must undergo specialized training and understand all safety guidelines before using the equipment.

Following these safety precautions will go a long way in preventing accidents and promoting a safe working environment.

A hot dust cover welding machine provided by Xihe is recommended: 1500 laser welding system.

The equipment has the function of quantitative production to reduce unnecessary waste. When one of the stations is loaded with products for automatic welding, operators can load and unload products from the other station, which greatly improves production efficiency.

The material is automatically unloaded to the waiting tray, enters the hydraulic cutting device through the servo drive, and automatically falls into the storage table. Modify and store material lengths via the color touchscreen.

It can accommodate covers for welding machine made of different materials and of different thickness levels, making them a versatile, multi-purpose tool for welding cover manufacturers. Furthermore, the equipment can be programmed and customized to meet a wide range of product specifications and requirements, increasing flexibility in manufacturing operations.

News

News

News