By Products

Welding Machine

By Application

Automation Production Line

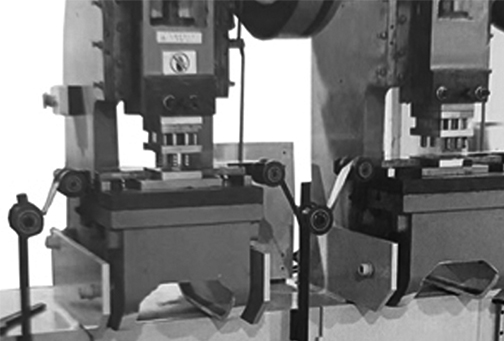

The equipment clamps its stainless steel strip with a welding fixture, and then welds the product through continuous laser welding. The conveyor belt connects various processes such as hemming, stretching, pressing, and chamfering, so that the G-ring can be fully automated from welding to forming. Production.

The operation is simple, and each process adopts the touch screen parameter control equipment. Adjust the stainless steel width according to the actual situation of the factory. The equipment achieves maximum efficiency through various transmission means. Laser continuous welding, the welding seam is smooth and beautiful.

One person can do the operation alone or all the processes. Equipped with high precision servo motor, the size is completely accurate. This equipment integrates the most advanced laser continuous welding technology. For different types of products, only need to change the mold to complete automatic processing. The equipment saves a lot of labor costs.

In the past, these processes required 5-6 people to complete, but now only one person can do it with high quality and efficiency. The equipment is very stable, all accessories are made of well-known brands at home and abroad, and all structures are optimized to achieve the most ideal state.

This equipment is mainly used for the automatic production of welding and forming of stainless steel strips for glass pot lids. According to the processing technology characteristics of G-ring and product quality requirements

All processing procedures adopt automatic clamping, automatic processing, automatic unloading, etc., and workers only need to load materials. The equipment saves a lot of labor, and the welded and formed products fully meet various quality requirements.

News

News

News