By Products

Welding Machine

By Application

Automation Production Line

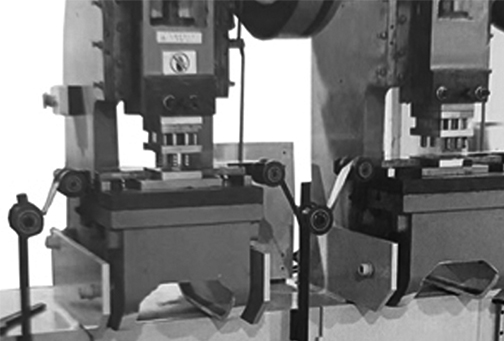

Reasonable distribution shall be adopted in combination with the brake assembly process. Using the flow channel transmission, the automatic manipulator completes the brake assembly process.

Laser marking, the laser marking machine can automatically engrave repeatedly to ensure clear words. Automatic gluing, perfectly matched with four-axis machinery, the equipment can be used stably for a long time.

Automatically screw the screw, can set the torque and the number of turns of the screw.Automatic flip, the design of automatic flip station on the runner subtly meets this demand.

Automatic oiling, four-axis robot + precision oiling parts, to achieve the oiling requirements of various specifications. Automatic detection, four-axis robot + laser sensor + program coding, 360 ° all-round detection of the brake.

The assembly line is divided into two sections, the head and the tail, and the installation and disassembly are more convenient. the plane conveying structure has a flow channel utilization rate of up to 100%.

The runner adopts 2.5 times differential chain heavy-duty transmission, which can realize product assembly of about 30kg. The volume is about 40m³, and it is easier to realize automatic and semi-automatic installation procedures.

News

News

News