By Products

Welding Machine

By Application

Automation Production Line

A brake shoe welder is a machine used to weld brake shoes to the brake pads of a vehicle. This brake shoe welder machine process is done to ensure that the brake pads can continuously stop the wheels of a car or truck. The brake shoe welder uses a high degree of pressure and temperature to melt and fuse the brake pads and shoes. The brake shoe grinder is then used to shape and size the welded assembly to fit the specific brake assembly. This process ensures that the brakes will perform correctly and safely. The grinder can also be used to remove any excess material created during the welding process.

Maintenance and repair are essential aspects of ensuring that brake shoe welders operate efficiently and produce quality results consistently. To maintain optimal performance and prevent downtime, regular maintenance checks and repairs are required.

General maintenance includes daily cleaning, checking electrical wiring, and ensuring that the cooling system is functioning correctly. Regular checks for leaks, cracks, and signs of wear on parts such as electrodes, weld heads, and cables are also necessary. Repairs should be performed by qualified technicians and should include thorough troubleshooting to identify the root cause of the problem.

Over time, brake shoe welder machines' components can wear or break due to prolonged use, which may lead to costly repairs or replacements if the issues go unresolved. Regular maintenance is crucial in mitigating this risk. Purchasing a genuine replacement part from the manufacturer is highly recommended to ensure maximum compatibility with the brake shoe welder.

Software upgrades and updates are also critical for the smooth operation of the brake shoe welder. Manufacturers frequently release new updates that improve the welder's functionality, ensure accuracy, and optimize outputs. Regular checks for updates and upgrades should be included in the maintenance routine.

Proper maintenance and repairs not only help extend the lifespan of brake shoe welder machines but also ensure that they operate within the required safety standards. It is recommended to follow the manufacturer's guidelines strictly to guarantee optimal performance and safety.

Brake shoe welder technology has seen significant advancements over the years, enabling faster, more accurate, and efficient welding processes. These advancements have improved overall productivity in various industries that use brake shoe welding machines. Here are some of the notable advancements:

Automation: Advanced robotics technology has enabled the automation of welding processes. This technology helps reduce labor cost, human error, and increase production capacity.

Digital Controls: Modern brake shoe welders have digital controls that allow operators to set and monitor key variables such as welding speed, temperature, time, and force. This has improved the accuracy and consistency of welds.

Advanced Sensors: Brake shoe welders now have advanced sensors that provide real-time data on the welding process, such as weld quality and material integrity. This helps operators diagnose problems and adjust the welding parameters accordingly.

Laser Technology: Laser welding technology offers higher precision, stronger, and cleaner welds compared to traditional welding methods. This technology also increases production speed and reduces the need for rework.

Smart Welding: Some brake shoe welder machines now have smart welding features that use artificial intelligence (AI) and machine learning to optimize welding parameters, improve weld quality, and provide predictive maintenance notifications.

In conclusion, the advancements in brake shoe welder technology have made welding processes more efficient, accurate, and automated. These advancements have also opened up new possibilities for innovation and are helping businesses stay ahead in an increasingly competitive environment.

High Welding Capacity:

Brake shoe welders must be able to weld a high volume of brake shoes continuously. They should be built with high-power, durable components and designed to handle heavy use over extended periods of time.

Precise Temperature Control:

The welding process requires precise temperature control to ensure a consistent quality of weld. The brake shoe welder should have advanced temperature sensors and controls that can maintain the optimal temperature range for welding operations.

Customizable Settings:

Different brake shoe materials and thicknesses require different welding settings. A good brake shoe welder should have customizable settings for temperature, welding speed, and other important variables.

Easy to Use: Brake shoe welder requires a skilled operator, but the welder itself should be designed with intuitive controls and easy-to-use features. The operator should be able to quickly task-switch between different brake shoe types and thicknesses with minimal downtime.

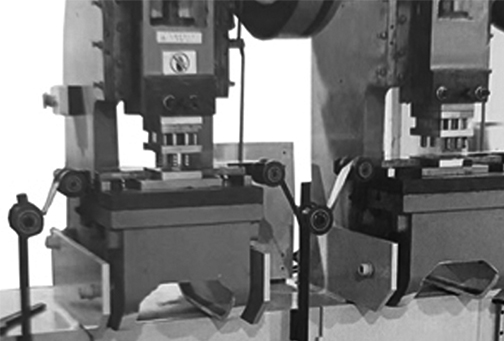

Brake shoe welder machines are designed to be versatile and work with a wide range of brake shoe material, including steel, aluminum, and composite materials. This allows the welder to be used in a variety of industries, including automotive manufacturing, heavy equipment repair, and railway maintenance.

Many brake shoe welders are designed to be portable, allowing them to be easily transported to job sites or used in confined spaces. These welders are typically lightweight and compact, making them a great choice for mobile applications.

Brake shoe welders are built to withstand the demanding operating conditions of industrial environments. Heavy-duty construction, high-quality materials, and advanced cooling systems ensure that the welder can operate continuously without overheating or breaking down.

Brake shoe welders are equipped with safety features such as automatic shut-off switches, heat-resistant gloves, and protective shields. These features help to prevent accidents and protect operators from burns, sparks, and other hazards associated with welding. Additionally, many welders are designed to be easy to use, reducing the risk of operator error and injuries.

News

News

News