By Products

Welding Machine

By Application

Automation Production Line

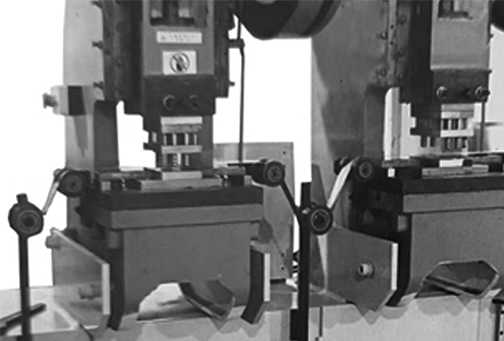

The Xihe stainless steel punching machine is carried out by using two 10T punching machines to form holes on a stainless steel belt. The stainless steel belt is driven by the material rack, the transmission wheel, the adjustment wheel, and the post-process laser welding machine so that the stainless steel belt passes through the ss punching machine at a uniform speed. By adjusting the adjustment wheel and program setting, the punch presses punch the stainless steel strip at the same interval, and the adjustment speed matches the welding speed. The two punches are equipped with two sets of custom dies so that the hole size and hole spacing of the stainless steel are unified.

The Xihe stainless steel punching machine combined with automatic laser welding equipment will be an ideal choice for automation. Our precision machinery ensures high-quality stainless steel punchings for sale.

Adjust the settings: Set the appropriate settings for the machine according to the type and thickness of the material being punched.

Store the machine properly: Store the machine in a dry and clean place. Cover it with a protective cover to prevent dust and debris from accumulating on it.

Lubricate the machine: Lubricate the moving parts of the machine regularly to ensure smooth operation. Use a lubricant recommended by the manufacturer.

Regularly clean the machine: After every use, clean the machine to remove any buildup of debris and oil. Use a clean cloth or a brush to wipe down the machine. Avoid using harsh chemicals that can damage the machine.

Check and replace worn parts: Regularly check the machine for any worn or damaged parts and replace them immediately. This will ensure that the machine is working properly and prevent any breakdowns or malfunctions.

Stainless steel punching machines are widely used in a variety of industries, thanks to their precision, speed, and versatility. Here are some common applications:

Automotive industry: Stainless steel punching machines are used to punch holes in various car parts, such as the body frame, exhaust pipes, and engine components.

Aerospace industry: Stainless steel punching machines are used to punch holes in aircraft parts, such as fuselage, wings, and engine components.

Construction industry: Stainless steel punching machines are used to punch holes in stainless steel sheets for various construction projects, such as building facades, balustrades, and railings.

Manufacturing industry: Stainless steel punching machines are used to produce parts for various machines and equipment, such as hydraulic systems, power tools, and electronic devices.

Medical industry: Stainless steel punching machines are used to produce medical implants, such as surgical screws and plates, as well as medical equipment and instruments.

Food and beverage industry: Stainless steel punching machines are used to produce stainless steel parts for food processing and packaging equipment, such as conveyor belts, tanks, and tubing.

Decorative industry: Stainless steel punching machines are used to punch decorative holes and patterns in stainless steel sheets for various applications, such as wall panels, furniture, and art pieces.

Overall, stainless steel punching machines are essential tools in many industries, where precision, speed, and versatility are key factors in achieving quality and efficiency.

Choosing the right stainless steel punching machine can be a crucial decision, as it can have a significant impact on the quality and efficiency of your production processes. Here are some factors to consider when selecting a stainless steel punching machine:

Punching capacity: Determine the maximum thickness and size of materials that the machine can punch, as this will affect the types of applications for which it is suitable.

Speed and accuracy: Consider the speed and accuracy of the machine, as this can impact the productivity of your processes and the quality of the finished product.

Features and options: Look for additional features and options, such as programmability, customization, automatic feeding and unloading, and tooling options to ensure that the machine can meet your specific needs.

Maintenance and support: Ensure that the machine is easy to maintain and that there is readily available support from the manufacturer or supplier in case of breakdowns or malfunctions.

Safety features: Check if the machine comes with safety features such as interlocks, fencing, and ergonomic controls to ensure the operator's and machine's safety.

Price and value: Evaluate the price of the machine and factors in the value it provides, such as productivity gains, reduced material wastage, and increased production capacity.

By considering these factors, you can identify the right stainless steel punching machine that best suits your specific needs, ensuring that your investment pays off in the long run.

Xihe is a renowned company specializing in the manufacturing and supply of custom metal punches, with a particular focus on stainless steel (SS) punching machines. With our extensive experience in the industry, we have established ourselves as a trusted name, providing high-quality punching solutions to various businesses.

Our custom metal punches are designed to meet the specific requirements of our clients, particularly in the stainless steel sector. We understand the versatility and importance of stainless steel in numerous applications, and therefore, our SS punching machines are engineered to deliver precise and accurate punches on stainless steel sheets of varying thicknesses. Whether you need to create holes, slots, or any other shapes, our machines are capable of handling it all.

At Xihe, we take immense pride in our state-of-the-art manufacturing facility, equipped with cutting-edge technology and machinery. Our team of skilled engineers and technicians works diligently to ensure that every SS punching machine we produce adheres to the highest standards of quality and performance. We utilize only the finest materials and components to guarantee the durability and longevity of our stainless steel punching machine.

Hot SS punching machine you might be interested in hydraulic press punching machine.

The equipment is equipped with two 10t punches and two sets of punching dies, so as to achieve high-speed and stable punching, and the burr of the product after 100000 times of punching can meet the requirements of user standards.

The equipment is equipped with two sets of adjustment wheels, which can easily and conveniently adjust different product diameters and welding seam positions at any time. At the same time, the equipment is equipped with material racks, frequency conversion feeding devices, line rail material storage devices, etc., which are simply connected to the welding machine.

Stainless steel punching machines are designed to produce high precision and accurate holes in stainless steel sheets. They can punch holes of various shapes and sizes, depending on the requirements of the application.

News

News

News