By Products

Welding Machine

By Application

Automation Production Line

Fire extinguisher for welding is designed to provide a quick and efficient means of welding the neck of fire extinguisher cylinders to the body of the cylinder. The fire extinguisher for welding works with a high-frequency welding method to fuse the neck to the body with heat generated from an electrical current passing through the metal.

The process is initiated by placing the fire extinguisher cylinder in the machine's fixture, which automatically positions and secures the cylinder in place. The neck and body of the cylinder are then held in place using the welding electrodes, which apply an electrical charge to melt the metal and fuse the neck to the body.

The welding electrodes are typically water-cooled to prevent overheating and allow for continuous operation. Additionally, automated systems can provide temperature control and monitoring to ensure consistent and high-quality welds.

Once the welding is complete, the machine releases the cylinder, and the operator can remove it from the fixture. The fire welding machine is an efficient and reliable method of welding the neck to the body of fire extinguisher cylinders, allowing for quick and high-quality production.

Welding fire extinguisher requirements are essential to ensure the safety and functionality of the extinguisher. A fire extinguisher welding machine can be used to meet these requirements, ensuring accurate welding and high-quality production. Fire extinguisher welding machines are highly precise pieces of automated equipment that can position, align, and weld the neck of fire extinguisher cylinders to their bodies. These machines utilize high-frequency welding, which ensures a strong and reliable weld that can withstand the wear-and-tear of use in an emergency situation.

To ensure that the welding fire extinguisher requirements are met, regular maintenance checks, and calibration are necessary to keep the welding machine performing at optimal levels. Calibration checks ensure that the machine meets the welding standards needed for high-quality fire extinguishers. Proper operator training is also important to ensure that the machine is operated safely and efficiently. By adhering to welding requirements when using a fire extinguisher welding machine, companies can produce quality fire extinguishers that can help prevent and control fires.

Fire extinguisher welding technology is an essential aspect of fire extinguisher production. As technology advances, there are several trends that are being observed in the industry. One of the main trends in fire extinguisher welding technology is the use of more advanced automation technology. With the use of artificial intelligence (AI), fire extinguisher welding machines can be programmed to make autonomous decisions regarding the welding process. This technology minimizes the need for human supervision, increases production efficiency and reduces the risk of errors during the welding process.

Another trend in fire extinguisher welding technology is the development of new welding techniques. Ultrasonic welding and laser welding are emerging technologies that promise to improve the quality of welds while reducing the risk of defects. These methods can help to reduce material waste, production time and cost.

With an increasing focus on sustainability, the trend of recycling materials is also shaping future fire extinguisher welding technology. By using recycled materials in production, fire extinguisher manufacturers can reduce their environmental impact while still producing high-quality products.

Going forward, increasing the level of automation in fire extinguisher welding machines, using emerging welding techniques and sustainable materials, are trends that will continue to shape the future of fire extinguisher welding technology.

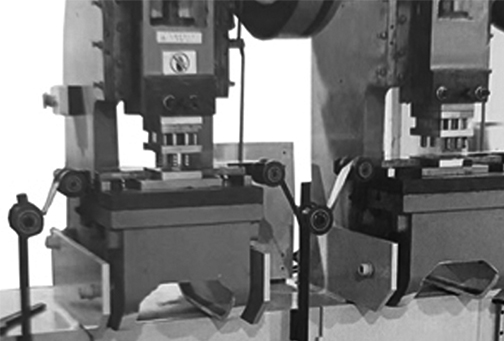

This equipment is a special equipment for welding the bottom and top of fire extinguishers. During the welding process, the operator is only responsible for assembling the semi-finished fire extinguisher cylinders on the designated material rack and arranging them in the required order. After the product is welded, it will be automatically unloaded to the finished floor stand.

The whole process is simple to operate, the equipment is small, the site space is saved, and it is easy to realize a fully automated production line. Automatic production, the operator only needs to place the material. High efficiency, high efficiency, the cylinder with a diameter of 180mm can weld 55 products per hour.

Sealed design reduces environmental damage to the operator's body. The operation is simple, and the operator can complete it according to the operating instructions. Detection function, the equipment has no material detection function, and the cylinder suspension climbing and bottle mouth alignment have automatic detection functions.

Equipment welding speed is fast. In the state of no alarm and material shortage, taking a cylinder with an outer diameter of 180mm as an example, 55 fire extinguisher cylinders can be welded per hour on average.

The welding part of the equipment consists of three stations, namely clamping station, bottle bottom welding station and bottle mouth welding station. The equipment is easy to operate and greatly improves the production efficiency.

With a fire extinguisher welding machine, there is less waste as the automated system ensures accurate positioning, alignment, and welding. This reduces material costs and the time required to fix faulty welds.

Welding with a fire extinguisher welding machine can improve safety in the workplace. The automated system reduces the risk of accidents associated with manual welding equipment, including burn injuries and exposure to dangerous fumes.

News

News

News