By Products

Welding Machine

By Application

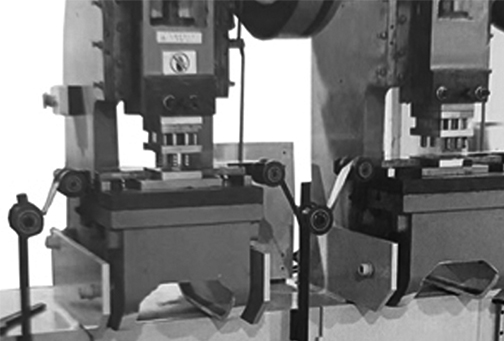

Automation Production Line

The equipment is mainly used for the automatic production of welding and forming of C-shaped small circles such as enamel cans. The material is fed by the driving wheel, then wound around the round seat, clamped, etc., the stainless steel strip is seamlessly welded by the continuous laser, and the robot arm grabs the welded product and performs the crimping process to complete the automatic production.

The equipment is mainly used for the automatic production of welding and forming of C-shaped small circles such as enamel cans. According to the characteristics of the C-type stainless steel ring width is relatively narrow and not thick, it is a customized automatic production line.

The welding speed is very fast, the welding seam is free of burrs, and the desoldering rate is less than 0.1%. Simple operation, full digital control, every worker can operate the equipment after learning.

Arbitrary adjustment, the equipment is controlled by the program, and the welding size can be adjusted arbitrarily. High-efficiency, high-precision servo systems are used to initiate various machining steps at high speed. High-quality laser continuous welding enables the weld seam to meet the highest demands.

The equipment occupies a small area and is very suitable for enamel pot manufacturers. The equipment adopts the most advanced continuous laser welding technology. The welding seam of stainless steel strip is smooth and flat, and the desoldering rate is very low.

After years of optimization and upgrading, the equipment has very stable operability. Using a robotic arm avoids the problem of workers getting on and off workpieces. So as to achieve the most ideal cost state.

News

News

News