By Products

Welding Machine

By Application

Automation Production Line

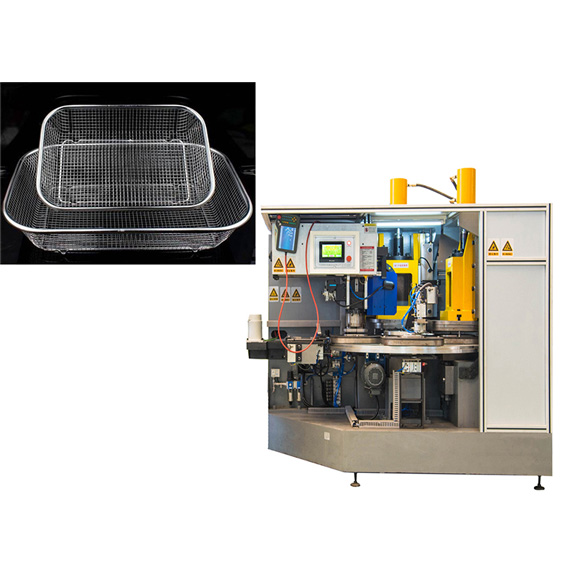

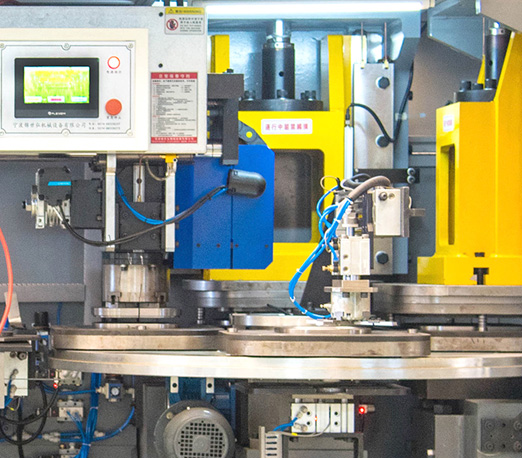

The equipment is a forming equipment designed for the special shape of products such as mesh basket, gas meter and oil lattice. The equipment is composed of four forming stations, with superior production capacity and less labor. The equipment accessories are processed by gantry machining center and slow wire walking precision machining to ensure the long-term stable operation of the equipment. The electrical components of the equipment are of international famous brands, effectively ensuring the long-term normal operation of the equipment.

Input voltage | Enter the frequency | Production speed | Product diameter | Product thickness | Product width | Dimensions |

3*380V | 50HZ | 9~15pcs/min | 63~600mm | <0.8mm | 12~40mm | 2300*1700*1800mm |

The equipment is mainly used in the stainless steel belt forming process of net basket, gas meter, oil grid and other products. The equipment combines the particularity of various product shapes to customize various supporting molds, so that the stainless steel basket can be formed at one time after welding. The equipment is easy to operate. The whole production process is controlled through the touch screen. It has high production precision, accurate positioning, accurate feeding, and no consumables.

After the products are welded by our welding equipment, the forming process of this kind of special products is completed by taking and placing the mechanical arm, taking and straightening preloading flattening, forming unloading and finished product blanking of the four position manipulator. The hydraulic oil of the equipment is cooled by compressed refrigerant, so that the equipment is in a long-term stable state.

mesh basket stainless steel belt four station forming machine Main Characteristics

the operation is simple, and the touch screen is used to control parameters throughout the process.

automatically complete curling, forming, unloading and other processes.

the equipment is composed of four position forming, with superior production capacity and less labor.

the hydraulic pressure of the equipment is cooled by compressed refrigerant.

customized mold production to meet the needs of special shapes.

the equipment has high production precision, accurate positioning and accurate feeding.